RIYADH METRO STATION

Our Mission

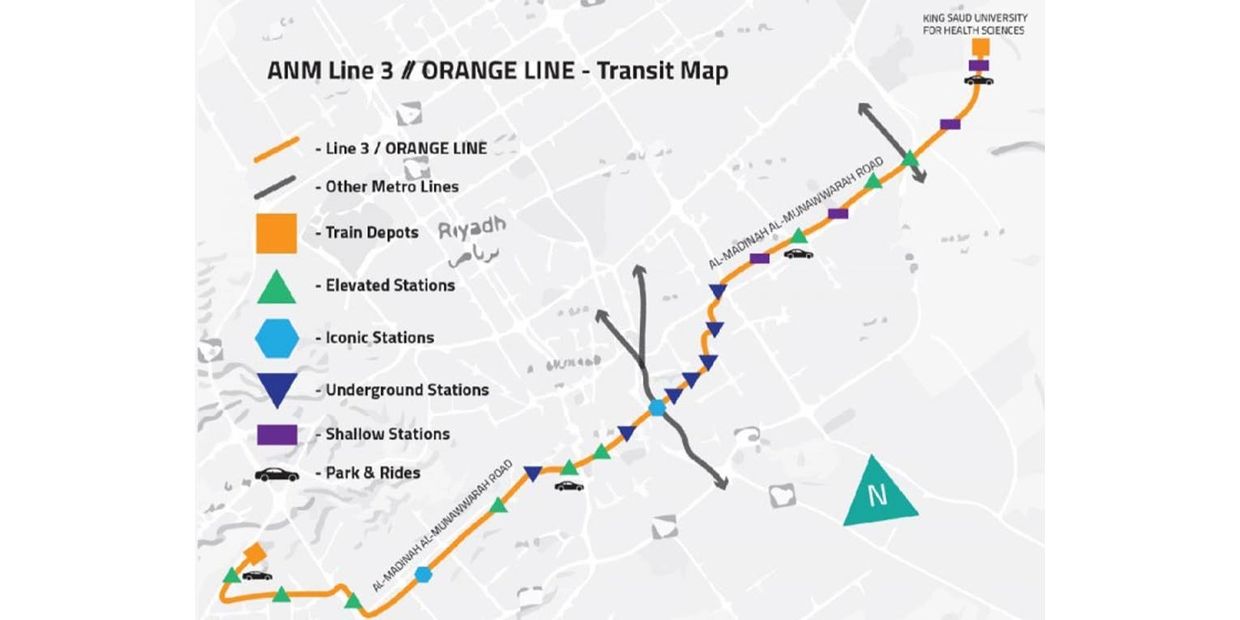

Line 3 Riyadh Metro Station (Orange line)

Line 3 Riyadh Metro Station

Line 3 is composed of 22 stations (including nine elevated, the iconic Downtown station and Western station), 2 depots and 6 park & ride. ACTE’s involvement in this gigantic project is to take over the installation of all façade works related to five elevated stations and two iconic stations.

Riyadh Metro Stations

• Elevated metro station: 3A1 station

• Elevated metro station: 3A2 station

• Elevated metro station: 3C2 station

• Elevated metro station: 3G1 station

• Elevated metro station: 3G2 station

• Iconic metro station: 3E2 station

• Iconic metro station: 3B2 station

Our Mission

We started our mission in May 2023, when we were awarded a contract from ANM consortium with the following scope of work:

• Study all the approved shop drawings to implement in the execution.

• Take exact site measures of the façade’s related missing items.

• Prepare detail execution drawings and cutting list for material orders.

• Receive, handle and transport the material to their specific location.

• Use different types of equipment (mobile cranes, manlift, electrical glass sucker ...) to safely install the façade as per approved shop drawings.

• Raise all relevant MRs, IRs and hand over the finished product.

• Repair, align, apply sealant to the already installed façade items and handover to the client.

Safety Award

For respecting and implementing the tough safety requirements for this project, we received a safety award from the reputable RMTC consultant.

Elevated Metro Stations

Riyadh Metro Station 3A1

1/5

Implementation

Frameless Glass

Frameless glass

Special design printed glass that forms an overall design located on the bridge of the station with supporting glass fins, stainless steel brackets and covers.

Curtain Wall

The used curtain wall is a specially designed section by TECHNAL France, original HIDRO accessories, embedded steel reinforcement that holds the adjacent grating and Aluminum perforated skin façade, with a special and super durable powder coating including high specification glass to reduce the heat with hinged doors to access the grating.

Grating

Galvanized steel with heavy duty powder coated grating attached to the curtain wall system, serving as technical walking passage between the curtain wall and the Aluminum perforated skin façade. It includes stairs and a special platform for the bridge glass.

Aluminum Perforated Skin

Galvanized steel with heavy duty powder coated grating attached to the curtain wall system, serving as technical walking passage between the curtain wall and the Aluminum perforated skin façade. It includes stairs and a special platform for the bridge glass.

Louvers

Special designed high-quality clip in TECHNAL louver system including mullions, louver blades, clip blades, steel brackets, bird mesh Rockwool that is covering external walls and mechanical rooms all over the façade of the station.

Aluminum Soffit

Made of 3 mm thick aluminum sheets, same color of the curtain wall, fixed at the bottom of the bridge to cover all MEP pipes.

Aluminum Composite panels (ACP)

Fire rated 4 mm thick special bronze and black color, installed on the roof, under the bridge, around the shops, on the track area and even curved above bridge glass.

GI Panels

Galvanized steel perforated anti slippery panels covering all the roof area.

Elevators

External elevators, free standing steel structure, covered with reflective blue glass, supported by stainless steel angles and curtain wall covers and caps from outside. The elevator is connected to the main station by a connecting small bridge.

Internal elevators, free standing steel structure, covered with clear glass, supported by stainless steel angles and curtain wall covers and caps from outside.

Internal Partitions

- Shaped TVM doors cut to size as per TVM machines, allowing easy access for maintenance.

- Ticketing Office Room: a full glass room with clear and back painted glass / faregate.

- Openable glass access panel to cover the rolling shutter with glass suspended ceiling.

- White back painted glass cladding with embedded firehose cabinets.

Iconic Station 3E2

RIYADH METRO STATION ICONIC STATION 3E2

We were fully present and working at full capacity at the 3E2 station (engineers, general supervisors, supervisors, lead men, safety officers, and technicians) supporting ANM in the handover of the project.

Our Presence

We were fully present and working at full capacity at the 3E2 station (engineers, general supervisors, supervisors, lead men, safety officers, and technicians) supporting ANM in the handover of the project.

Our Involvement

Our assistance spanned on two and a half months and included various tasks such as installing glass balustrades, internal partitions, ACP cladding, and fixed glass partitions.

Iconic Station 3B2

RIYADH METRO STATION ICONIC STATION 3B2

Our scope at the 3B2 station included the installation of 13 entrance airlocks (U-channel and fixed glass system), adjustment of the steel brackets, and installation of curved glass panels for 6 circular elevators and 1 rectangular elevator. Additionally, we installed the steel transoms and the top parametric glass on both the curtain wall elevation and the track area elevation.

Our Presence

We executed six circular elevators with 10.10.4 tempered laminated glass, installed using painted steel brackets welded onto circular steel columns. Each elevator has a height of 15 m and a diameter of 4 m.

We also executed one rectangular elevator measuring 6 × 4 m, with a height of 15 m. The glass is installed using painted steel brackets welded onto square steel columns.

Our Involvement

We executed thirteen entrance airlocks, consisting of fixed glass panels installed using top and bottom U-channels, with all the steel structures covered by ACP panels

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.